- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Alúmina (AL2O3) Fabricantes, Proveedores, Fábrica

Alumina ceramics are a type of advanced ceramic material that is primarily made of aluminum oxide and the general purpose of ceramists. They are in great demand because of their remarkable comprehensive properties, some of which include high hardness, high wear resistance, and high temperature resistance. These will maintain their structure at very high temperatures. Additionally, alumina ceramics have high electrical insulation and chemical resistance, and very high mechanical strength. While brittleness will limit them. They possess all those properties which has resulted in alumina ceramics playing a central role in the semiconductor industry.

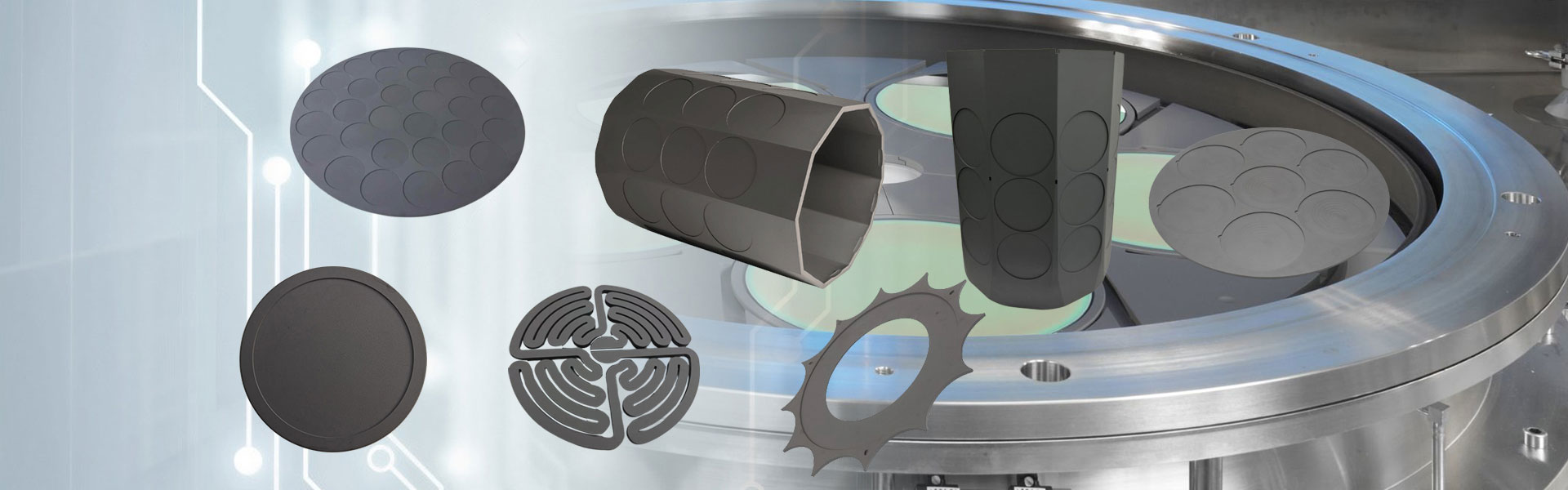

The vacuum chuck will be attached to the vacuum equipment via a connecting pipe. When the chuck comes in contact with the workpiece, i.e., a sheet or film, the vacuum equipment will activate and draw negative pressure in the chuck. The workpiece is carried by atmospheric pressure thus it will cling firmly to the chuck allowing the processing to go on without issue. When the workpiece is done being processed the vacuum machine will stop and the chuck will gradually fill with air. The workpiece will separate of its own accord thus finishing the clamping, processing and handling processes.

Black Alumina ceramic is one of the primary materials used in vacuum chucks. It is primarily composed of Al2O3, with transition metal oxides as colorants and sintering aids added. The process is then sintered at a specific temperature. Vacuum chucks made from porous ceramic feature ultra-fine micrometer-level pores and spacing, enabling reliable handling of thinner and more delicate workpieces. Furthermore, these chucks can accommodate workpieces of varying sizes, eliminating the need to maintain a fixed set of shapes and sizes for each workpiece, thus saving costs and improving efficiency.

Alumina ceramics have a high elastic modulus and specific stiffness, are resistant to deformation, and have a low coefficient of thermal expansion and high thermal stability. They are an excellent structural material and are currently widely used in aviation, aerospace, petrochemicals, machinery manufacturing, the nuclear industry, and microelectronics.

Alumina ceramic components offer excellent properties such as high hardness, high mechanical strength, exceptional wear resistance, high temperature resistance, high resistivity, and excellent electrical insulation. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature. They play an irreplaceable and important role in semiconductor manufacturing production lines, covering nearly all semiconductor manufacturing equipment and serving as key components. Alumina ceramic components are primarily categorized by application, including annular and cylindrical types, airflow guides, load-bearing and fixed types, hand-grip gaskets, and modules.

- View as

Tablero de fibra de alúmina policristalina

El tablero de fibra de alúmina policristalina es un material de placa refractaria de alto rendimiento con excelente resistencia al choque térmico, fuerte resistencia a la corrosión y resistencia superior a la oxidación. Este rendimiento refractario lo hace ampliamente utilizado en entornos desafiantes de alta temperatura, incluidos hornos de alta temperatura, hornos de alta temperatura, reactores de alta temperatura, tuberías de alta temperatura, puertas de hornos de alta temperatura y paredes de hornos de alta temperatura. Al elegir Semicorex, se beneficiará de precios altamente rentables, servicios personalizados de personalización y una calidad excepcional del producto.

Leer másEnviar ConsultaBoquillas cerámicas personalizables

Fabricadas con minuciosa atención al detalle, las boquillas cerámicas personalizables de Semicorex son la solución genial para controlar el caudal de gases y líquidos con una uniformidad y precisión incomparables. Semicorex espera con interés su consulta adicional.

Leer másEnviar ConsultaMandriles electrostáticos de cerámica

Los mandriles electrostáticos cerámicos Semicorex son componentes de adsorción electrostática de precisión hechos de cerámica de alúmina y nitruro de aluminio de alto rendimiento, que utiliza el principio de adsorción electrostática para sujetar y fijar obleas. Es ampliamente utilizado en los campos de fabricación de semiconductores. Semicorex cuenta con tecnología avanzada, materiales de alta calidad y productos rentables. Esperamos convertirnos en su socio proveedor confiable en China.

Leer másEnviar ConsultaManipulador de cerámica de alúmina

El manipulador cerámico de alúmina Semicorex es un componente de equipo semiconductor de alto rendimiento hecho de alúmina de alta pureza, diseñado específicamente para el manejo preciso de obleas libres de contaminación. Este manipulador tiene las características de limpieza excepcional, estabilidad superior, alta precisión, eficiencia mejorada y rendimiento confiable, lo que lo convierte en su opción ideal.

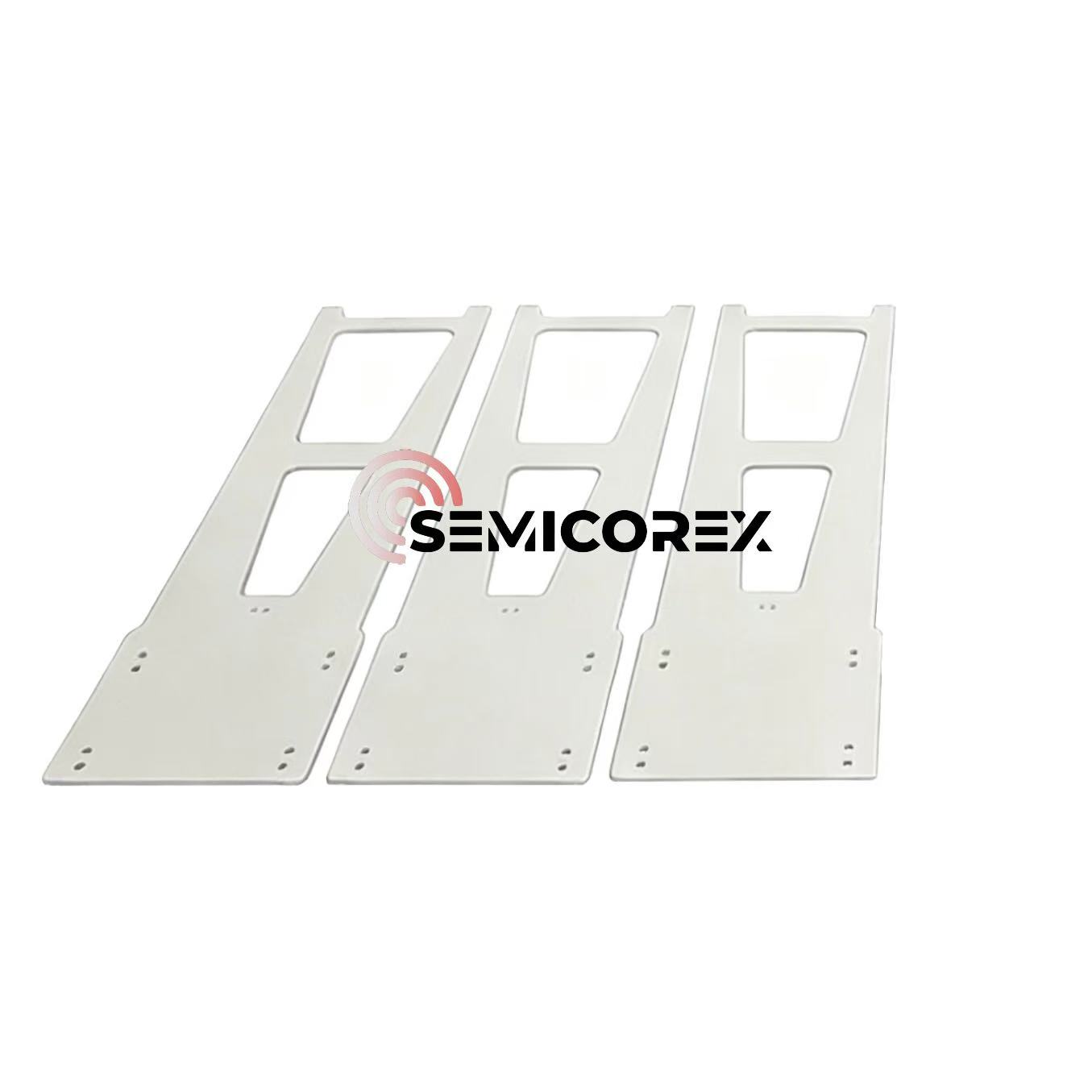

Leer másEnviar ConsultaPlacas base de montaje de alúmina

Las placas base de montaje de alúmina semicorex son un componente de cerámica de alto rendimiento diseñado para un manejo preciso de obleas en la fabricación de semiconductores. Su fuerza superior, aislamiento y estabilidad térmica lo hacen ideal para exigir entornos de automatización de la sala limpia.*

Leer másEnviar ConsultaBrazo robot de alúmina

El brazo robot de alúmina semicorex es un componente de cerámica de alto rendimiento diseñado para un manejo preciso de obleas en la fabricación de semiconductores. Su fuerza superior, aislamiento y estabilidad térmica lo hacen ideal para exigir entornos de automatización de la sala limpia.*

Leer másEnviar Consulta