- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Alúmina (AL2O3) Fabricantes, Proveedores, Fábrica

- View as

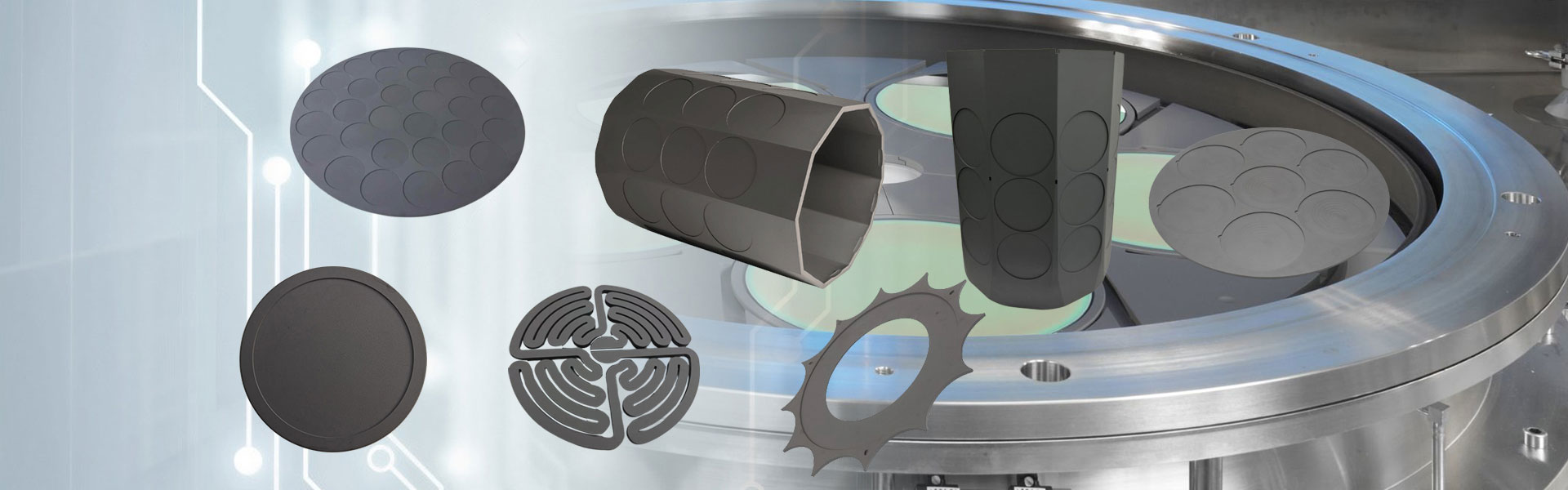

Alúmina Ceramic End Effector

El efector de la alúmina de alúmina semicorex es un componente de ingeniería de precisión diseñada específicamente para un manejo de obleas confiable y sin contaminación en la fabricación de semiconductores y aplicaciones relacionadas.*

Leer másEnviar ConsultaPortabrocas de cerámica porosa

El mandril de cerámica porosa Semicorex (mandril de vacío) es una herramienta de alta precisión diseñada para sujetar de forma segura obleas durante los procesos de fabricación de semiconductores. Al elegir Semicorex, usted se beneficia de una solución que ofrece rendimiento, durabilidad y opciones de personalización excepcionales, lo que garantiza una mayor eficiencia de producción y estándares de calidad consistentes.*

Leer másEnviar ConsultaMandriles de vacío de alúmina

Los mandriles de vacío de alúmina Semicorex son componentes diseñados con precisión para sujetar de forma segura obleas o sustratos durante procesos críticos de fabricación de precisión y semiconductores. Con el compromiso de Semicorex con materiales de alta calidad y técnicas de fabricación de vanguardia, nuestros mandriles de vacío de alúmina brindan confiabilidad, precisión y rendimiento inigualables para sus aplicaciones más exigentes.*

Leer másEnviar ConsultaMandril de vacío

Semicorex Vacuum Chuck es un componente de alto rendimiento diseñado para una manipulación segura y precisa de obleas en la fabricación de semiconductores. Elija Semicorex por nuestras soluciones avanzadas, duraderas y resistentes a la contaminación que garantizan un rendimiento óptimo incluso en los procesos más exigentes.*

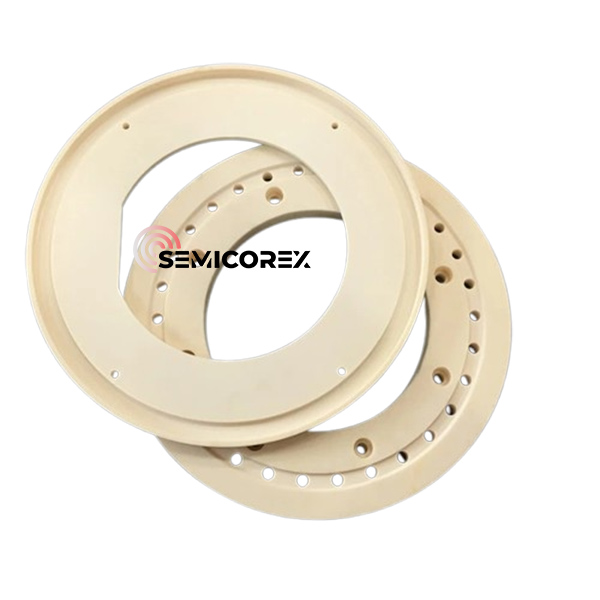

Leer másEnviar ConsultaAnillo de aislamiento de alúmina

El anillo aislante de alúmina Semicorex se emplea como aislante en varios componentes eléctricos; sus excelentes propiedades de aislamiento eléctrico garantizan un rendimiento confiable en aplicaciones donde prevenir la conducción eléctrica es esencial.

Leer másEnviar ConsultaPortador de pulido de oblea de alúmina

La aplicación del portador de pulido de obleas de alúmina Semicorex en diversas industrias, desde semiconductores hasta energía fotovoltaica, desempeña un papel crucial en los procesos de molienda y pulido químico mecánico (CMP) de obleas.

Leer másEnviar Consulta