- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China SI Epitaxy Fabricantes, Proveedores, Fábrica

- View as

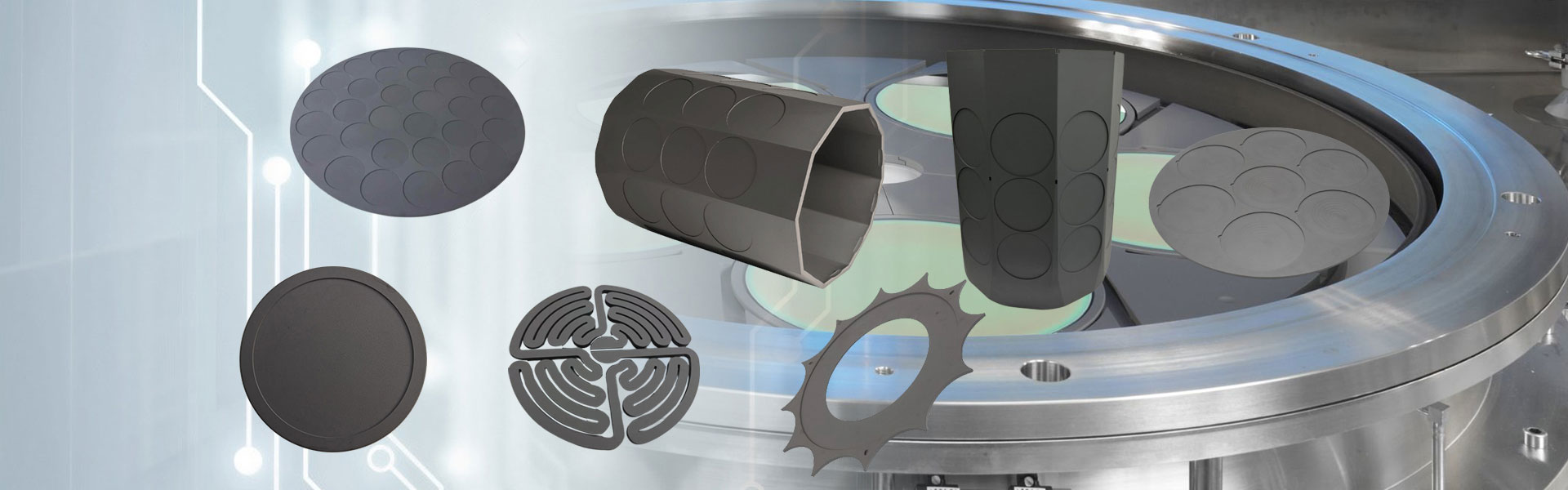

Susceptor de barril con revestimiento de SiC

Semicorex Barrel Susceptor con revestimiento de SiC es una solución de vanguardia diseñada para elevar la eficiencia y precisión de los procesos epitaxiales de silicio. Elaborado con meticulosa atención al detalle, este susceptor de barril con revestimiento de SiC está diseñado para cumplir con los exigentes requisitos de la fabricación de semiconductores, sirviendo como soporte óptimo para obleas y facilitando la transferencia perfecta de calor a las obleas. Semicorex se compromete a ofrecer productos de calidad a precios competitivos y esperamos convertirnos en su socio a largo plazo en China.

Leer másEnviar ConsultaBarril de SiC para epitaxia de silicio

Semicorex SiC Barrel For Silicon Epitaxy está diseñado para cumplir con los exigentes requisitos de los materiales aplicados y las unidades LPE. Elaborado con precisión e innovación, este susceptor en forma de barril está fabricado con grafito recubierto de SiC de alta calidad, lo que garantiza un rendimiento y una durabilidad excepcionales en aplicaciones de epitaxia de silicio. Semicorex se compromete a ofrecer productos de calidad a precios competitivos y esperamos convertirnos en su socio a largo plazo en China.

Leer másEnviar ConsultaSusceptor de grafito con revestimiento de SiC

El susceptor de grafito Semicorex con revestimiento de SiC es un componente esencial diseñado para procesos de epitaxia de silicio en materiales aplicados y unidades LPE (epitaxia en fase líquida). Fabricado con material de grafito de alta calidad recubierto con carburo de silicio (SiC), este susceptor garantiza un rendimiento y una longevidad superiores en entornos de fabricación de semiconductores. Semicorex se compromete a ofrecer productos de calidad a precios competitivos y esperamos convertirnos en su socio a largo plazo en China.

Leer másEnviar Consulta