- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

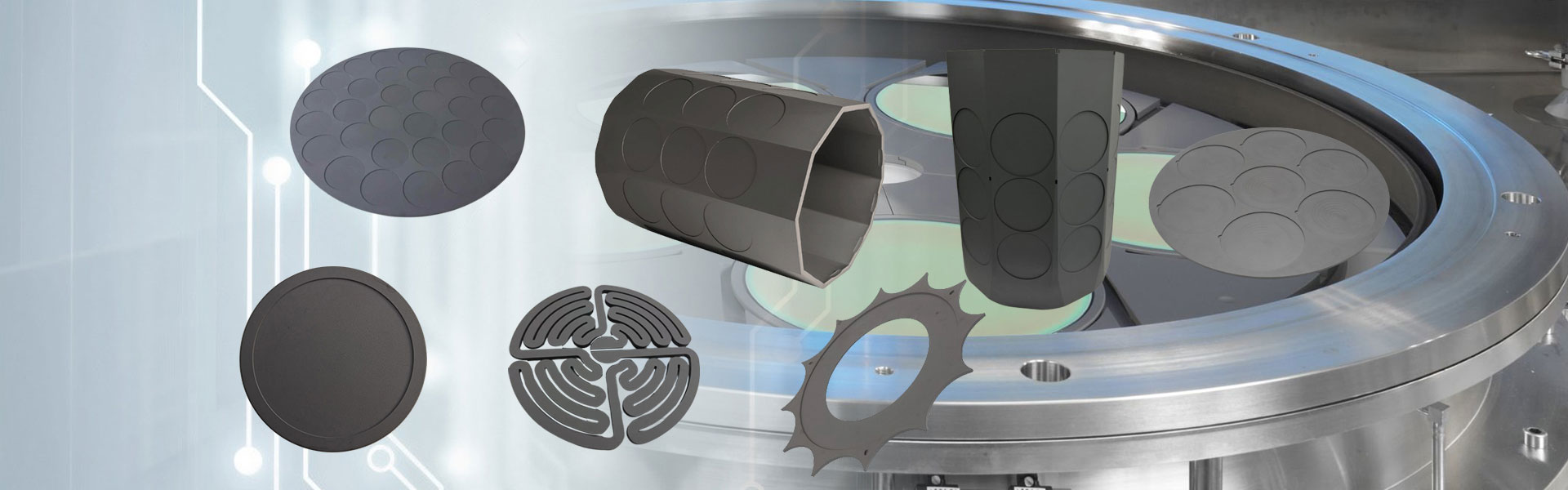

China Grafito isostático Fabricantes, Proveedores, Fábrica

- View as

Buje de grafito de bronce

El casquillo de grafito de bronce Semicorex tiene las características de alta capacidad de carga, resistencia al impacto, resistencia a altas temperaturas, fuerte capacidad de autolubricación y también puede resistir la erosión y la abrasión de líquidos corrosivos. Este casquillo de grafito de bronce es particularmente adecuado para equipos que funcionan en condiciones de trabajo complejas en entornos sin aceite, de alta temperatura, de alta carga, de baja velocidad, antiincrustantes, anticorrosión y antirradiación.

Leer másEnviar ConsultaRodamientos autolubricantes

Los rodamientos autolubricantes Semicorex son un tipo de rodamiento que combina las propiedades autolubricantes de los materiales de grafito. Se utilizan ampliamente en campos industriales con altos requisitos de lubricación y condiciones ambientales complejas.

Leer másEnviar ConsultaCalentador de varilla de grafito

El calentador de varillas de grafito semicorex es un elemento de calentamiento de alto rendimiento diseñado para una generación de alta temperatura uniforme dentro de los hornos de vacío. Elija Semicorex para su experiencia en soluciones de grafito con ingeniería de precisión, ofreciendo una estabilidad térmica superior y un rendimiento duradero adaptado a sus necesidades industriales.*

Leer másEnviar ConsultaVarilla de electrodo de grafito

Las varillas de electrodos de grafito semicorex son componentes de grafito de alta pureza utilizados como elementos de calentamiento de núcleo en hornos de vacío. Elija Semicorex para la calidad de material inigualable, el mecanizado de precisión y el rendimiento confiable en entornos de vacío de alta temperatura.*

Leer másEnviar ConsultaPlacas superiores de grafito

Las placas superiores de grafito semicorex son accesorios con ingeniería de precisión diseñados para un manejo seguro y confiable de botellas de vidrio caliente en entornos de fabricación de alta temperatura. Elija Semicorex para la calidad de material inigualable, las capacidades de mecanizado personalizadas y el rendimiento consistente confiado por los principales productores de vidrio en todo el mundo.*

Leer másEnviar ConsultaCrisoles de grafito

Crucenos de grafito semicorex diseñados para un control de estabilidad térmica y contaminación excepcionales en procesos de crecimiento de cristales semiconductores. Elija nuestros crisoles de grafito para una pureza, rendimiento y confiabilidad inigualables en el crecimiento del cristal de semiconductores. *

Leer másEnviar Consulta