- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Cuarzo Fabricantes, Proveedores, Fábrica

- View as

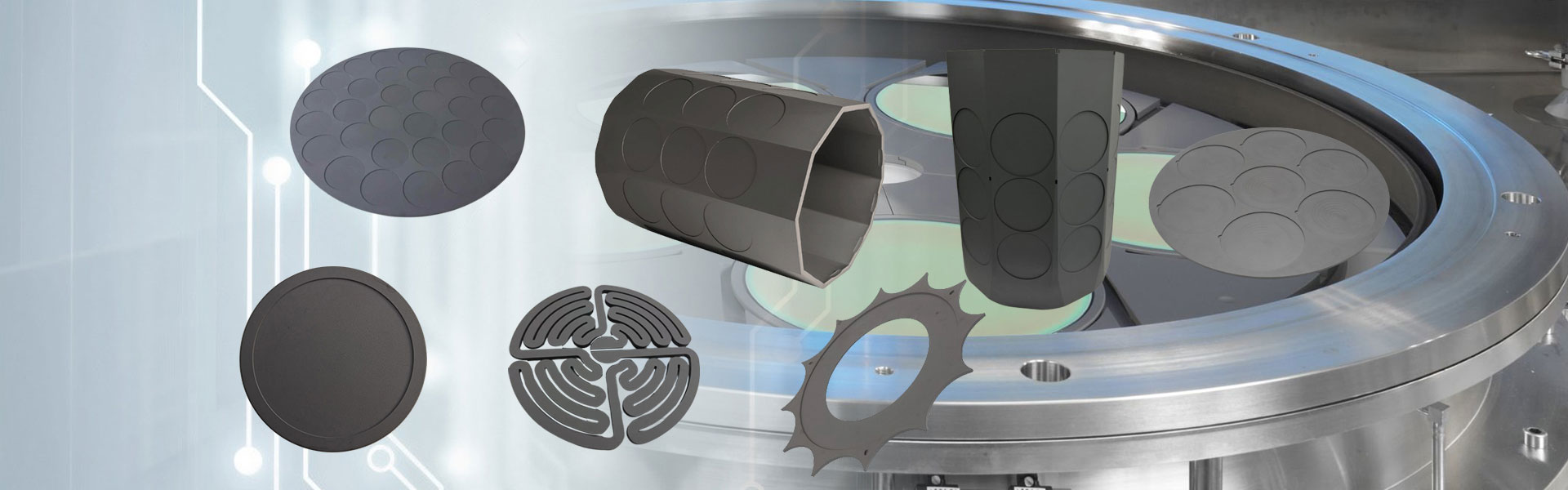

Crucbles de cuarzo de semiconductores

Los crisoles semiconductores semiconductores son contenedores de cuarzo fusionados de alta pureza diseñados para el exigente proceso de extracción de silicio de un solo cristal en la fabricación de semiconductores. Elegir semicorex significa beneficiarse de una tecnología de crisol de múltiples capas avanzada, pureza de material excepcional y un estricto control de calidad que garantiza una calidad de cristal superior y un rendimiento de producción constante.*

Leer másEnviar ConsultaCrisoles de cuarzo fusionado

Los crisoles de cuarzo fusionado semicorex son contenedores de alta pureza diseñados para el crecimiento del cristal de semiconductores, que ofrecen una estabilidad térmica excepcional y resistencia a la contaminación para la producción de obleas sin defectos. Elija Semicorex para el control estricto de la pureza de la pureza, la fabricación de precisión y la confiabilidad comprobada en los procesos de semiconductores más exigentes del mundo.*

Leer másEnviar ConsultaCrisoles de cuarzo

Los crisoles de cuarzo semicorex son herramientas indispensables en la industria fotovoltaica, lo que garantiza el crecimiento exitoso de cristales de silicio de alta calidad en condiciones extremas. Los crisoles de cuarzo semicorex ofrecen un rendimiento, confiabilidad y adaptabilidad incomparables, lo que los convierte en la opción ideal para los fabricantes que se esfuerzan por la excelencia en la producción de energía solar.*

Leer másEnviar ConsultaCrisoles de cuarzo de alta pureza

Los crisoles de cuarzo de alta pureza Semicorex son un componente crítico en la industria de los semiconductores, diseñados para el crecimiento de alta precisión del silicio monocristalino. Los productos de Semicorex, conocidos por su calidad y confiabilidad excepcionales, brindan soluciones líderes en la industria para los procesos de fabricación más exigentes.*

Leer másEnviar ConsultaCrisol de cuarzo

El crisol de cuarzo Semicorex está diseñado para usarse en el crecimiento monocristalino de materiales semiconductores, lo que garantiza un rendimiento y una calidad del cristal óptimos. Elija Semicorex por nuestra artesanía superior, ingeniería de precisión y compromiso de ofrecer productos que cumplan con los más altos estándares de la industria.*

Leer másEnviar ConsultaSoporte para barco de oblea de cuarzo

El soporte para barcos de obleas de cuarzo Semicorex es un componente indispensable en la producción de obleas semiconductoras y células fotovoltaicas, ya que ofrece propiedades de material y características de diseño excepcionales, garantiza la estabilidad de las obleas y mejora los resultados del proceso.

Leer másEnviar Consulta